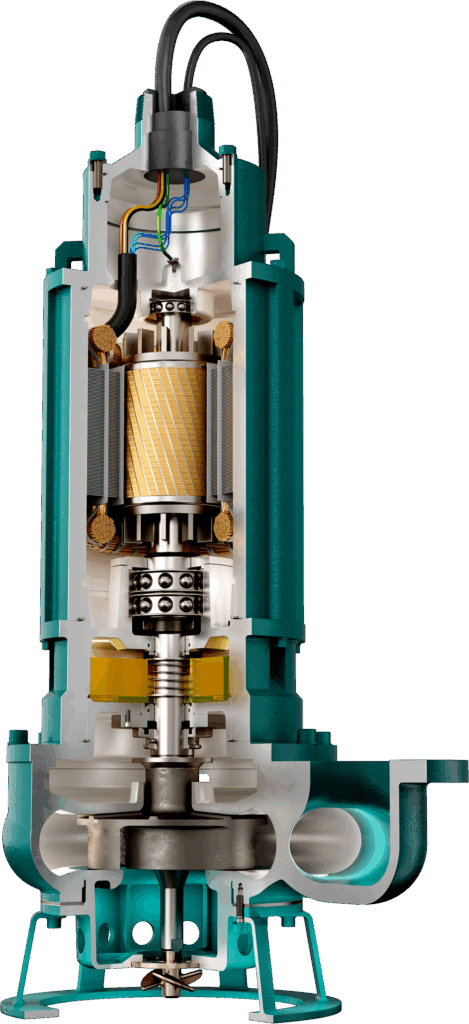

Continuous Run Dry Capable Motor

Submersible motors are available in a variety of duty specific configurations:

- Standard Non-Explosion Proof

- Continuous in Air Non-Explosion Proof

- Explosion Proof UL listed Class 1 Group C&D in air or submerged

- F-Class Insulation 40°C (104°F) ambient

- H-Class Insulation 60°C (140°F) ambient

- High Temp rated motors to 90°C (194°F) and 95°C (203°F)

- Low Temp rated motors to -25°C (-13°F)

- 380, 460 and 575 Volt

Design features common to all motor configurations:

- Rubber compression fitting for primary cable entry

- Epoxy potting to bare, butt spliced lead and control wires

- External thread boss to accept conduit or additional cable seal element

- Integral lifting lugs with optional lifting bail available

- Minimum 2 motor thermostats or optional RTDs to sense thermal overload

- Dual moisture sensor probes

- Heavy duty cast ductile iron motor housing

- O-Ring sealed, deep socket motor housing registers

- Machined stator housing to stator core fit for maximum heat transfer

- 416 Stainless shaft, 316 Stainless or 17-4PH optional

- Heavy Duty Ball Bearings, sealed and greased for life

- 316 Stainless fasteners, Alloy 20 fasteners optional

- Mechanical Seal chamber Oil Fill / Drain ports

- Click Here for Technical Details